Ejection Rubber Dilemma

Durometer or Compression/Deflection?

For years we’ve been using the durometer as the preferred method of selecting different types of ejection rubber. This type of measurement might help compare one kind of rubber/elastomer to another, but it does not tell us how well it will perform on a die. The proper comparison method to use in determining which type of elastomer would work best on a particular die is a test method called Compression/Deflection, not durometer.

Let me explain:

Using the Durometer Measurement Process

Durometer is the measurement of firmness, or surface tension, of a compressible material. There are nine primary durometer measurements ranging from Type A to Type M. Our industry typically uses two different scales: OO and A scales. The method used to determine the durometer value is the same with either scale and completed by using a tool as pictured below.

This tool pushes a pin into the surface of the material, and the amount of resistance the material surface exerts against the pin is the value used in defining the durometer of a material. The difference between the two scales is that OO uses a pin with a wider rounded tip, whereas the A scale uses a narrower sharp pin that has a small blunt tip. Typically the OO scale is used in measuring the firmness of softer materials like light foams and sponge rubber. For example, the OO scale would measure the softness/hardness of a seat cushion. The wider rounded tip of the OO pin allows for resistance when pushed into the soft foam. The resistance is measured to identify the durometer value.

The A scale measures denser/harder materials such as rollerblade or skateboard wheels. The sharp pin of the A scale can press into the surface to record a measurement. If the rollerblade wheel is measured using the wider rounded tip of the OO scale, it would have so much resistance that it would not create any depression. On the other hand, if a soft foam is measured using the sharp pin of the A scale, the pin would just penetrate the material without any resistance, and again no measurement could be recorded.

The Problem With Using Durometer Measurements to Qualify Ejection Materials

In our industry, the softness or hardness isn’t what matters. For us, the spring force of the rubber determines the right rubber for a particular job. Consider what one instinctively does when comparing two different pieces of rubber. They squeeze it between their thumb and forefinger to determine if the rubber will work in their application. This test more closely represents Compression/Deflection rather than Durometer.

Using the Compression/Deflection Measurement Process

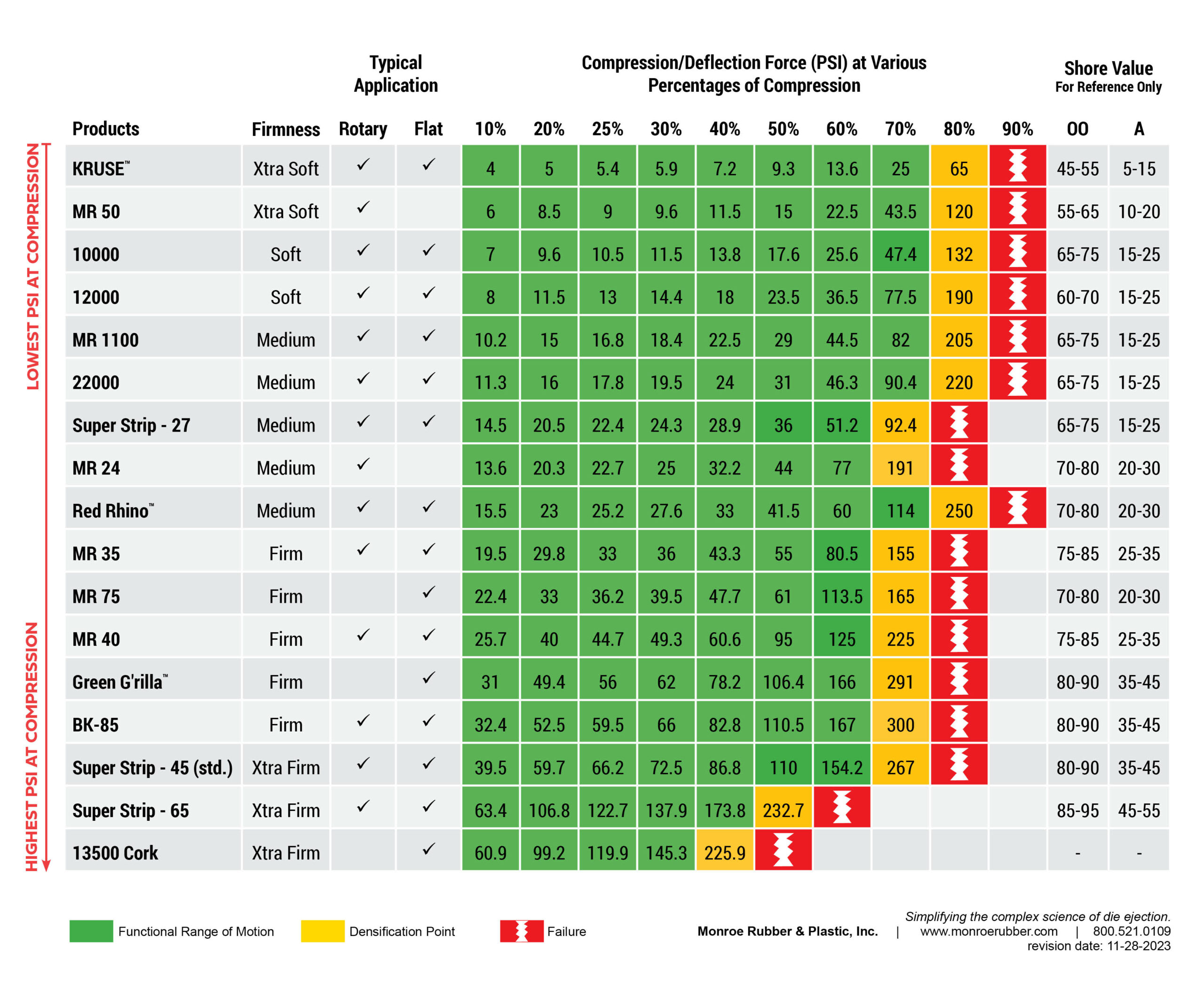

Compression/Deflection is the measurement of the spring force of a piece of rubber/elastomer. It measures the PSI (pounds per square inch) of force the rubber generates at different percentages of compression. For example, Red Rhino generates 20 PSI at 20% compression and 31 PSI at 30% compression. A simple math equation determines what percentage of compression a piece of elastomer will reach during a diecutting job.

Rubber Ht – (Rule Ht – Board Ht) + Substrate Thickness + Anvil Penetration

Rubber Ht

= Percentage of Compression

Once this value is known, it can be used in the Functional Range of Motion chart below to determine the PSI of the various types of rubber under that percentage of compression. This chart will lead to an informed decision on which rubber will function best in your application. Within the colored boxes is the PSI value under the various compression percentages.

Using the Functional Range of Motion Chart

The Functional Range of Motion is the amount of compression a piece of rubber can withstand and function properly. In other words, it is the compression range where a piece of rubber can compress and snapback repeatedly without premature wear or failure. This is the green zone. The yellow zone is the densification point. The yellow zone is where the rubber now becomes solid and can no longer compress. If we were talking about springs, this is where all the coils on the spring would be touching. Once the amount of compression reaches this point, the rubber becomes densified, and the life of that piece will be compromised.

Go beyond the yellow value, and you are in the red zone, which is where the piece of rubber will fail and break apart.

Using Compression/Deflection as opposed to durometer changes the paradigm that has been used for years in our industry in determining which rubber to use on a die. Using Compression/Deflection to choose the right ejection material will help your jobs get on and off press quickly.

To see more on the Function Range of Motion Chart, click here.

Back to Blog